Introduction — the crisis and a seed of solution

Humanity’s materials system is at a crossroads. The global demand for affordable, high-performance synthetic textiles and ropes has driven economic growth — but it has also created a planetary-scale problem: plastic pollution, significant carbon footprints, and increasing landfill and microplastic burdens. In 2020–2025 the world produced hundreds of millions of tonnes of plastic and more than a hundred million tonnes of textile fibres annually, with synthetics (polyester, polypropylene, nylon) making up the majority of new fiber production. These trends drive greenhouse gas emissions and marine pollution while creating urgent pressure to shift toward a circular bio-economy that valorizes agro-wastes — for example, banana agro-waste — into biodegradable, low-carbon textiles and ropes. This article examines the scale of the problem (plastic pollution, synthetic rope/textile footprint), quantifies banana agro-waste, and outlines how banana fibres can be mobilized within circular bio-economy pathways to advance SDGs and climate action. (Our World in Data)

1. Global sustainability challenges in materials & textiles

1.1 Scale of textile production and emissions

Global fibre production has roughly doubled in two decades and continues to grow: recent market reports put global fibre production above 120 million tonnes per year (2022–2024), with polyester and other synthetics accounting for ~55–70% of that volume. This growth has translated into a substantial climate and waste footprint: the fashion/textile sector is responsible for several percent of global greenhouse gas emissions and produces tens of millions of tonnes of post-consumer textile waste annually. (Textile Exchange)

1.2 Textile & rope industries: emissions, waste, microplastics

Synthetic-based ropes and technical textiles (made from polypropylene, nylon, polyester) are energy-intensive to make — requiring fossil feedstocks, polymerisation, extrusion, and texturation. These processes embed significant cradle-to-gate emissions. In addition, use-phase abrasion and end-of-life mismanagement release microplastics to soils and waterways (washing, abrasion, lost fishing gear, discarded/moored ropes). The Ellen MacArthur Foundation and UNEP have repeatedly warned that the current linear model (make → use → discard) is environmentally unsustainable and economically wasteful. (Ellen MacArthur Foundation)

2. The problem of plastic pollution & synthetic rope/textile footprint

2.1 Marine plastics and microplastics — the dimensions

The world generates on the order of ~300–350 million tonnes of plastic waste per year; studies estimate 1–2 million tonnes of that enter the oceans annually and tens of millions of tonnes leak into the environment in other ways, with persistent ecological harm. UNEP estimates roughly 19–23 million tonnes of plastic leak into aquatic ecosystems per year in recent assessments. Synthetic ropes and marine gear (fishing nets, mooring ropes, lines) are recognised point-sources of macro- and microplastic pollution when lost, abraded, or discarded. (Our World in Data)

2.2 Carbon intensity — life-cycle figures for plastics & ropes

Life-cycle assessments (LCAs) of polyolefins (e.g., polypropylene, PP) and polyamides (nylon) show the polymer production stage is a major contributor to total greenhouse gas (GHG) emissions. Published cradle-to-gate numbers for PP resin production commonly fall in the ~1.3–3.5 kg CO₂e per kg PP range (method and boundaries vary); more product-level LCAs (e.g., climbing or technical ropes) report dozens of kg CO₂e per rope driven by polymer production and processing. For example, a rope LCA found base polymer production accounted for roughly half of a climbing rope’s footprint (study result ≈ 46.6 kg CO₂e per rope for a specific polyamide rope). These numbers show that substituting high-volume synthetic polymers at scale directly reduces product carbon footprints. (MDPI)

2.3 Durability vs persistence — degradation timelines

One reason synthetics are ubiquitous is durability: polypropylene, polyester, and nylon resist biodegradation and many ropes last years under service conditions. However durability in service becomes persistence in the environment: depending on polymer type and exposure, degradation times range from decades to centuries, with fragmentation into microplastics occurring far sooner than molecular biodegradation. Experimental field work demonstrates fragmentation and slow tensile loss over months to years, but full mineralisation can take many decades under ambient conditions. Natural-fiber alternatives biodegrade orders of magnitude faster in biological environments, reducing long-term microplastic loads. (Nature)

3. Banana agro-waste: scale and opportunity

3.1 Global banana production — how much waste?

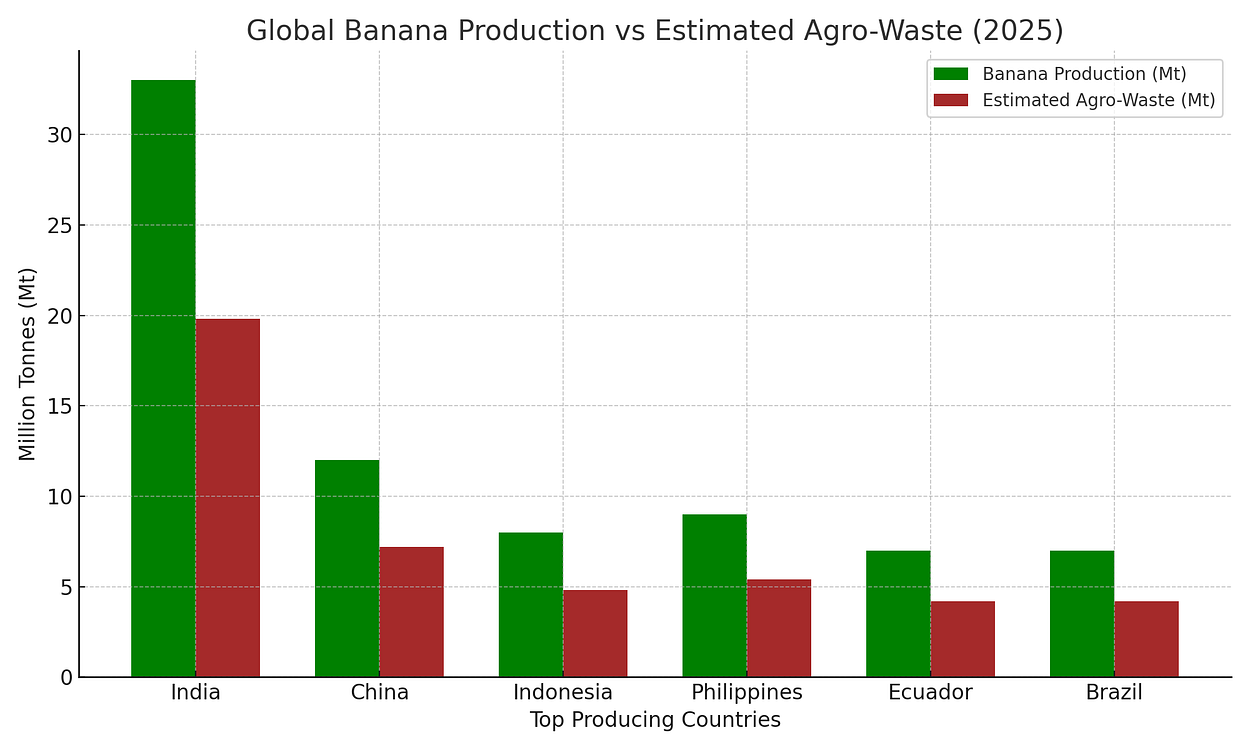

Bananas are among the world’s most widely produced fruits. FAO and market reviews report global banana production on the order of ~130–140 million tonnes per year in recent years (2020–2024), concentrated in tropical regions of Asia, Africa and Latin America — with India, China, Indonesia, the Philippines, Ecuador, and Brazil among leading producers. Importantly for circular value chains, ~50–60% (and in many reports 60–80% of plant biomass) of the banana plant (pseudostem, rachis, leaves, peels) becomes post-harvest agro-waste; the pseudostem alone accounts for a large share of lignocellulosic residues that are currently under-utilised. That yields tens of millions of tonnes of potentially extractable fibre and biomass annually. (FAOHome)

3.2 Regional insights & livelihood potential

The bulk of banana biomass waste is generated in tropical producing regions (Southeast Asia, South Asia, West & Central Africa, Latin America). For smallholder suppliers and processing facilities, converting pseudostem and rachis residues into fiber or value-added products creates new income streams and local industry opportunities (fiber extraction units, small-scale spinning/weaving, rope-making cooperatives). Recent studies estimate that a hectare of banana cultivation may generate hundreds of tonnes of biomass residues per year — a substantial feedstock if collected and processed. (Taylor & Francis Online)

Global banana production and agro-waste (2025)

4. From waste to product: banana fibres in the circular bio-economy

4.1 How banana agro-waste supports the circular bio-economy & SDGs

Transforming banana agro-waste into fibres, ropes, and composite materials aligns with core circular bio-economy principles — turning biological residues into durable, reusable, and biodegradable materials while retaining carbon in products for the product’s lifetime. This approach connects directly to several SDGs:

- SDG 12 (Responsible Consumption & Production): reduces waste and creates value from residues.

- SDG 13 (Climate Action): displaces fossil-based synthetics, lowering embodied emissions and enabling carbon storage in biogenic products.

- SDG 9 (Industry, Innovation & Infrastructure): stimulates local manufacturing innovation (low-cost extraction equipment, small enterprise rope/textile production). (PMC)

4.2 Case studies & evidence of feasibility

Between 2020 and 2025, multiple academic and pilot-scale projects have validated the potential of banana pseudostem fibers as a sustainable raw material for textiles, composites, and eco-friendly consumer goods. Studies have shown that banana fibers can be mechanically or chemically extracted, treated for durability, spun into yarns, woven into fabrics, and applied as reinforcement in polymer composites, ropes, and mats.

Comparative life-cycle assessments (LCA) of plant-derived fibers such as hemp, jute, flax, and emerging banana fiber research consistently demonstrate lower cradle-to-gate CO₂ emissions per kilogram compared with fossil-based polymers. In addition, plant fibers offer the unique advantage of temporary biogenic carbon storage while in use, extending their climate benefits beyond substitution effects.

Evidence from pilot projects and early-stage enterprises highlights banana fibers as both technically feasible and commercially viable. Startups across South Asia and Africa have successfully launched banana fiber ropes, mats, handwoven textiles, and home décor products for domestic markets and niche international buyers. These initiatives confirm both consumer demand and the market acceptance of natural alternatives to synthetic fibers.

A leading example from Pakistan is Natural Fiber Company (NFC), established in 2022. NFC has pioneered the solar-powered extraction of banana fibers, creating a zero-synthetics, handmade product line that includes body loofahs, face loofahs, slippers, clutch bags, coasters, rugs, and tote bags. By partnering with rural women artisans, NFC integrates circular economy principles, rural livelihood generation, and climate action into its business model. To date, NFC has processed tens of thousands of banana stems, diverting them from open burning and instead transforming them into high-value export-ready products.

NFC’s work demonstrates that banana fibers are not only scientifically feasible but also economically and socially impactful when implemented through localized, community-driven systems. The company has filed two patents (for its extraction machine technology and fabric-making process) and holds two trademarks — for “Natural Fiber Company” and “Yaram” — to protect its innovations and branding in global markets.

More details on NFC’s mission, products, and impact can be found at: 🌍 www.naturalfibercompany.com.

5. Challenges & research needs

Converting banana agro-waste into large volumes of rope/textile faces technical and logistic barriers: consistent collection and drying of pseudostems; scalable low-cost extraction and retting that preserve fiber length and strength; improving fibre durability and UV/water resistance without negating biodegradability; standardisation and certification for technical applications; and full LCA-based validation across supply chains. Research and investment are needed in automated extraction machinery, eco-friendly fibre treatments, hybridization with other fibres, and circular business models (take-back, composting, local circular hubs). (MDPI)

Conclusion — act now: policy, industry, research

The materials and textile sectors face an urgent sustainability imperative. Synthetic ropes and textiles, while technically performant, are a major source of plastic pollution, microplastics, and embodied carbon. At the same time, banana agro-waste — abundant in major producing regions — offers a practical low-carbon feedstock for biodegradable ropes, textiles and composites that fit a circular bio-economy. Scaling this transition will require coordinated action: R&D to improve fiber extraction and treatment; targeted industrial policy and incentives; investment in small-scale processing enterprises; and supply-chain commitments from brands and maritime industries to adopt low-carbon, low-microplastic alternatives. The win is systemic: reduced plastic pollution, lower embodied emissions, local livelihoods, and meaningful progress toward SDGs 9, 12 and 13.

Call to action: manufacturers, policymakers and researchers should co-invest in pilot processing facilities in banana-producing regions; fund LCAs to robustly quantify benefits at scale; and create procurement pathways (public and private) that prefer low-carbon, biodegradable ropes and textiles. The circular bio-economy is not an abstract ideal — it is a practical route to sustainable materials that must be accelerated now. (UNEP — UN Environment Programme)

0 comments