Introduction

Global industries from shipping and fishing to construction depend heavily on synthetic ropes made from nylon and polypropylene. These polymers deliver very desirable strength, abrasion resistance and long service life — which is why they dominate markets for mooring lines, trawl gear, safety lines and industrial hoists. But that durability has a dark side: synthetic ropes are petroleum-derived, carry substantial embedded greenhouse-gas emissions from resin production and processing, and — when lost or discarded — become persistent sources of plastic pollution and microplastics in marine and terrestrial environments. Recent assessments place the climate burden of primary plastics production in the order of gigatonnes CO₂e and highlight plastics as a major contributor to future emissions pathways. (ScienceDirect)

Natural-fiber ropes (banana, sisal, hemp, coir, jute and others) present a contrasting profile: the feedstock is renewable, often derived from agricultural residues or low-input crops; fibers are biodegradable at end-of-life; and their cultivation sequesters biogenic carbon during growth, partially offsetting cradle-to-gate emissions. In this article we compare the environmental impacts of synthetic and natural ropes using LCA evidence (2020–2025 literature), examine biodegradability and carbon benefits, and highlight circular-economy pathways and practical challenges for scaling natural alternatives. (MDPI)

1. Environmental impact of synthetic ropes

1.1 Production processes — nylon & polypropylene

Nylon (typically Nylon 6 or Nylon 6,6) is produced from petrochemical monomers via energy-intensive polymerisation and spinning steps; feedstock extraction, steam cracking and intermediate synthesis (caprolactam or adiponitrile) account for most upstream emissions. Polypropylene (PP) is a polyolefin produced by polymerising propylene derived from refinery cracking; its cradle-to-resin production energy and emissions are generally lower than those for nylon. Large LCA databases and synthesis reports show a clear pattern: per-kilogram cradle-to-resin GHG burdens for common engineering polymers vary considerably by polymer type and region, but nylon is consistently among the higher-emission plastics while PP is lower. (climatiq.io)

1.2 Typical LCA numbers (range & context)

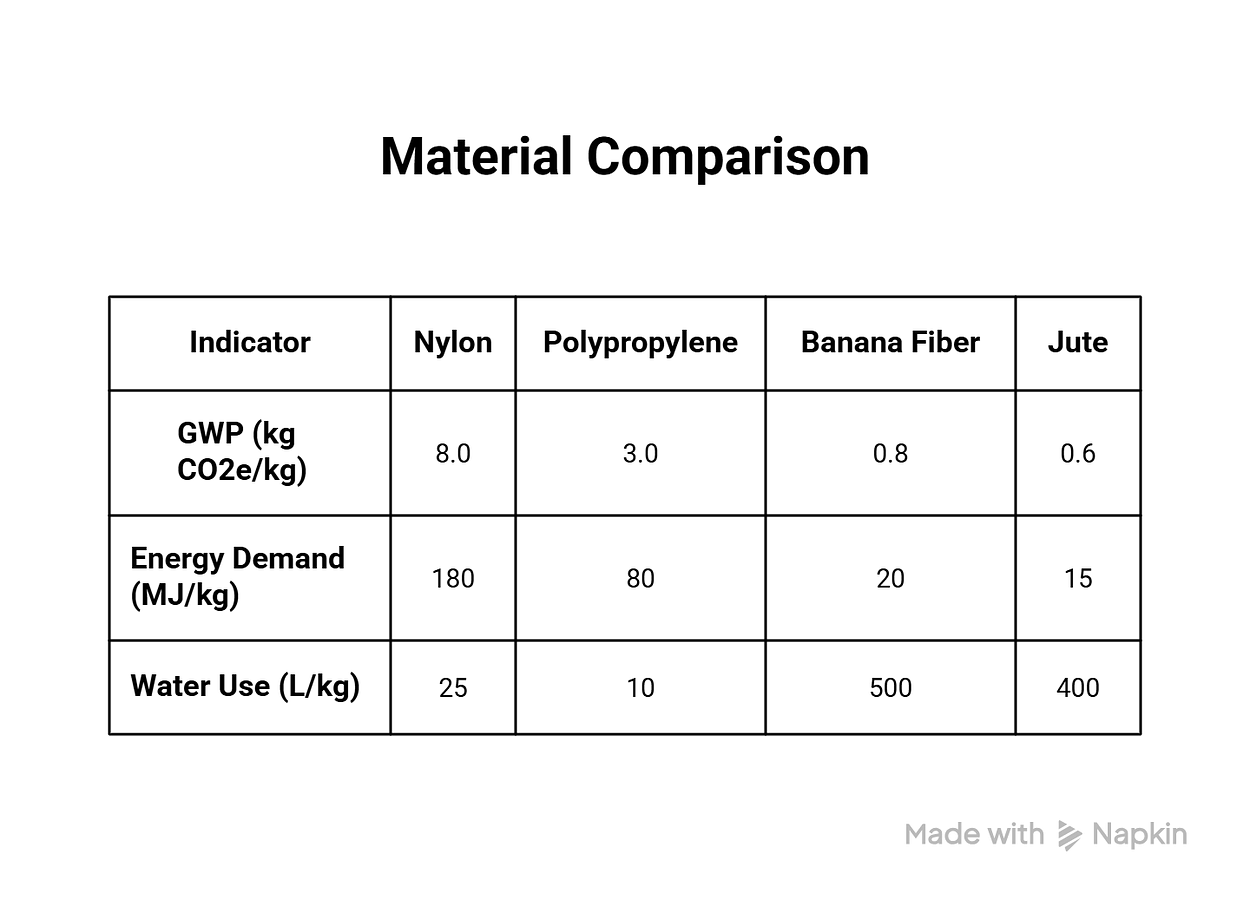

Published LCA source data and emission-factor compendia provide ranges rather than a single fixed value: recent meta-analyses and reporting place typical cradle-to-resin values for nylon in roughly the ~6–10 kg CO₂e per kg band (depending on polymer grade, process and allocation rules), while polypropylene often falls in the ~1.5–4 kg CO₂e per kg range. These ranges reflect differences in energy mixes, co-product allocations, and whether recycled content is included. (For plastics as a whole, primary production contributed >2 GtCO₂e in 2019 in sectoral analyses.) Use these ranges as LCA-aware estimates rather than absolute constants. (eta-publications.lbl.gov)

1.3 Longevity & pollution risk

Durability is an advantage during use but a liability after loss: synthetic ropes fragment slowly and are a source of microplastics. Lost gear and discarded ropes contribute to marine macro-debris and microplastic loads; recent research on fishing gear and shoreline debris highlights ropes, nets and lines as significant microplastic sources with long environmental residence times (decades to centuries). (ScienceDirect)

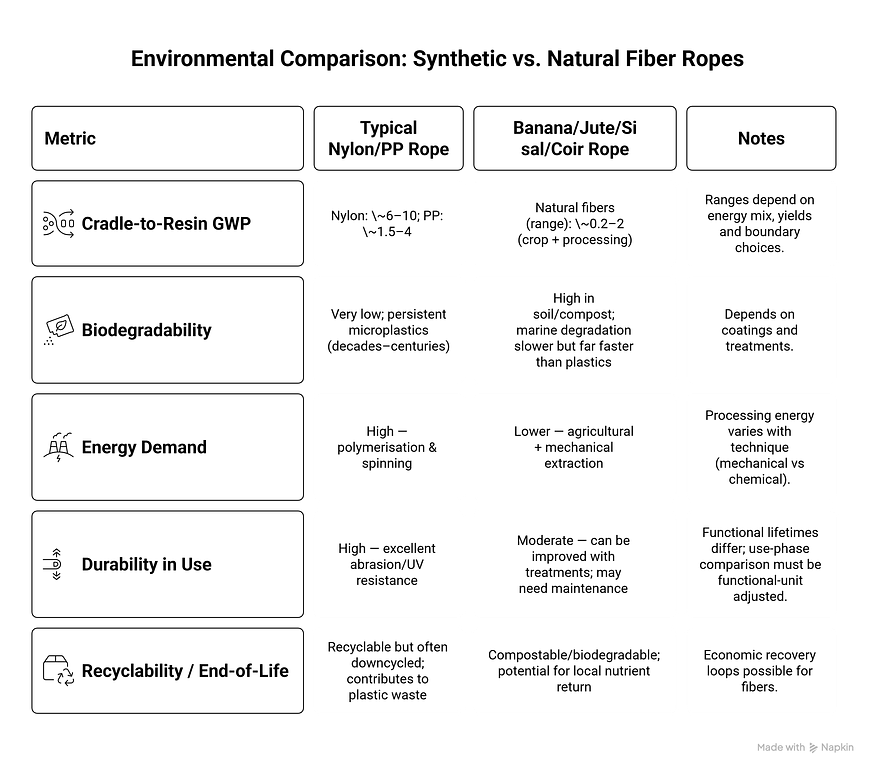

Figure 1 illustrates representative cradle-to-resin GWP ranges for nylon (6–10 kg CO₂e/kg) and polypropylene (1.5–4 kg CO₂e/kg) alongside selected natural fibers (see Section 2). Data represent aggregated LCA ranges from polymer reports and fiber LCA literature and are meant to show order-of-magnitude differences; exact values depend on system boundaries and local production conditions. (eta-publications.lbl.gov)

2. Environmental advantages of natural-fiber ropes

2.1 Feedstock, cultivation and waste valorization

Natural fibers come from annual crops or agricultural residues. Banana fibers, for example, are extracted from banana pseudostems — an agricultural by-product that would otherwise be waste. Jute, sisal, coir and hemp are cultivated specifically for fibers, often on marginal land and with relatively low synthetic-fertilizer input compared with commodity row crops in intensive systems. This creates opportunities for waste valorization (banana pseudostem → fiber → rope), rural income generation, and circular bioeconomy models. (e3s-conferences.org)

2.2 Lower embodied energy & biogenic carbon storage

On a mass basis, many natural fibers show substantially lower upstream fossil-fuel energy demand and GHG emissions than petrochemical polymers. Studies that compare fiber types (cotton, jute, flax, hemp, etc.) using cradle-to-gate LCA methods consistently find lower GWP for natural fibers when agricultural emissions and processing energy are modest and when biomass carbon sequestration is accounted for appropriately. Jute cultivation has been reported to sequester substantial CO₂ per hectare and to produce fibre with relatively low cradle-to-gate emissions in several LCAs. (eiha.org)

2.3 Biodegradability & end-of-life

Natural ropes biodegrade under appropriate conditions (aerobic composting, soil burial, marine biodegradation is slower but still far faster than synthetic plastics), thereby reducing persistent microplastic formation and long-term landfill burden. Biodegradability reduces the long tail of environmental risk associated with synthetic ropes. However, end-of-life rates depend on fiber treatment, coatings and environmental conditions — untreated jute, sisal and banana fibers will break down much faster than polymer-coated or resin-impregnated products. (Frontiers)

Metric Typical nylon / PP rope Banana / Jute / Sisal / Coir rope Cradle-to-resin GWP (kg CO₂e/kg) ~1.5–10 (polymer dependent) (eta-publications.lbl.gov) ~0.2–2 (crop + processing; region dependent) (eiha.org) Biodegradability Very low (centuries) — microplastic source (UNEP — UN Environment Programme) High under compost/soil; marine slower but biodegrades vs plastics (Frontiers) Energy demand (MJ/kg) High (polymerisation + processing) (eta-publications.lbl.gov) Lower (agriculture + mechanical extraction) (eiha.org) Durability in use High (excellent abrasion & UV resistance) Lower abrasion resistance; treatments/coatings can improve performance (PMC) Recyclability Technically recyclable but downcycling common (plasticsrecycling.org) Compostable / reuse; fiber recovery possible in some loops (FAOHome)

3. Life Cycle Assessment (LCA) comparison — scope and indicators

3.1 LCA scope choices matter

Comparative LCA must define system boundaries: “cradle-to-gate” (seed/farm → fiber or resin at factory gate) vs “cradle-to-use” or “cradle-to-grave” (including use, maintenance and end-of-life). For ropes, the use phase (service life, breakage, maintenance) and end-of-life (loss at sea, landfill, burning, composting) are critical. A bellwether finding in fiber LCAs is that although natural fibers often have lower cradle-to-gate GWP, shorter service life can offset benefits if replacement frequency is high — therefore, functional-unit parity (e.g., “rope that performs X hours of service”) is essential. (MDPI)

3.2 Key indicators to compare

Use common LCA indicators: GWP (kg CO₂e), cumulative energy demand (MJ), water use (m³), and waste/marine pollution risk. Where possible, include benefits of biogenic carbon uptake (accounting per IPCC guidance and LCA standards) and avoid double counting of biogenic removals. (eta-publications.lbl.gov)

Figure 2 shows hypothetical comparative bars using representative literature ranges: nylon GWP >> PP GWP >> natural fibers (banana/jute) when measured cradle-to-gate, but real-world outcomes depend on service life and system boundaries. Data sources: polymer LCA reports and fiber LCAs (2020–2024). (eta-publications.lbl.gov)

4. Carbon benefits & circular-economy validation

4.1 Biogenic carbon & sequestration

Natural fibers store biogenic carbon during plant growth; when fibers are used in long-lived products that avoid combustion, part of that carbon is temporarily sequestered and can be credited in some carbon accounting frameworks (subject to rules on permanence and double counting). This sequestration, together with lower fossil-energy inputs in processing, can produce net carbon benefits when natural ropes replace petroleum-based equivalents on a functional-equivalent basis. (eiha.org)

4.2 Carbon credits & substitution potential

There is growing interest in recognising substitution credits where biogenic products replace higher-carbon materials, but credible claims require robust LCA, clear counterfactual scenarios, and adherence to recognized carbon standards. Where rigorous LCA shows a measurable per-unit GWP reduction, an aggregator or project developer could potentially include rope substitution in a wider land-use or product-based crediting mechanism — though market acceptance and methodological rules vary. (VTT’s Research Information Portal)

This pathway reduces raw-material extraction, provides rural livelihoods, and keeps biomass carbon in local cycles where possible. Case studies from FAO and regional bioeconomy reports highlight the potential for rural development and export markets. (FAOHome)

Case Example: The Natural Fiber Company (NFC), Pakistan

A leading innovator in South Asia, The Natural Fiber Company Pvt. Ltd. (NFC) demonstrates how banana pseudostems can be upcycled into high-performance, biodegradable products such as ropes, loofahs, slippers, bags, and textiles. Based in Pakistan, NFC operates with a 100% solar-powered production system and specializes in patented fiber-extraction and fabric-making technologies that ensure consistent fiber quality and scalable production.

By valorizing agricultural waste that would otherwise be discarded or burned, NFC reduces open-field emissions while creating livelihood opportunities for rural families, especially women. Each month, the company processes tens of thousands of banana stems, converting 10% into strong natural fibers and 90% into organic liquid fertilizer — thereby supporting both the textile and agricultural sectors in a closed-loop system.

NFC’s model aligns closely with global circular-economy and climate goals:

- Biogenic Carbon Benefits: Every kilogram of banana fiber produced stores biogenic carbon and displaces petrochemical-based fibers such as polypropylene.

- Biodegradability: At end-of-life, NFC’s rope and textile products degrade naturally, avoiding the persistent pollution associated with synthetic ropes.

- Socio-economic Impact: NFC aims to train and employ 4,000 rural families by 2030, positioning Pakistan as a hub of natural-fiber innovation.

With registered trademarks (“Natural Fiber Company”) and patent filings for extraction technology, NFC is export-ready and open to white-label and collaborative partnerships worldwide.

More information: 🌍 www.naturalfibercompany.com

5. Challenges and opportunities

5.1 Key challenges

- Performance variability: natural fibers vary by cultivar, climate and processing — leading to inconsistent tensile and abrasion properties compared with engineered polymers. (PMC)

- Service life & maintenance: untreated natural ropes weather faster than synthetic ropes; bridging this gap often requires coatings that can reduce biodegradability or increase embodied impacts. (Frontiers)

- Standards & testing: international standards for rope testing (e.g., tensile testing, abrasion) exist, but material-specific standards and acceptance criteria for natural ropes (marine applications, safety critical lines) need harmonization. (PMC)

5.2 Opportunities & innovations

- Hybrid & composite ropes: blending natural fibers with low amounts of high-performance fibers or using bio-based coatings can create high-performance, lower-carbon products. (ScienceDirect)

- Localized value chains: converting agricultural residues (banana pseudostems, coir husks) into ropes creates rural employment and reduces transport-intensive supply chains. (e3s-conferences.org)

- Policy & procurement leverage: maritime and construction procurement rules that value life-cycle benefits (not just upfront cost) can accelerate adoption. International climate frameworks and circular-economy funds may support pilot projects and standards. (VTT’s Research Information Portal)

Conclusion

Synthetic ropes (nylon, polypropylene) deliver outstanding mechanical performance and have underpinned modern shipping, fisheries and construction — but their petrochemical origins, non-biodegradability and large cradle-to-gate emissions carry substantial environmental costs, including contribution to climate change and persistent microplastic pollution. Natural-fiber ropes (banana, jute, sisal, coir, hemp) offer compelling environmental advantages: lower upstream fossil-fuel emissions on a mass basis, biogenic carbon sequestration during growth, biodegradability at end-of-life, and strong circular-economy narratives built on waste valorization and rural livelihoods. (eta-publications.lbl.gov)

Realizing the substitution potential requires careful LCA on a functional unit basis (equal service over time), investment in processing and coatings that improve durability without eliminating biodegradability, and coordinated standards and procurement policies that reward life-cycle performance. For industry, policymakers and researchers, the path forward is clear: rigorous LCA validation, pilots for hybrid products, and circular-economy supply chains can unlock carbon benefits and reduce the plastic legacy of ropes — while creating socio-economic value for fiber-producing communities. (MDPI)

0 comments