Introduction — global context and why pseudostems matter

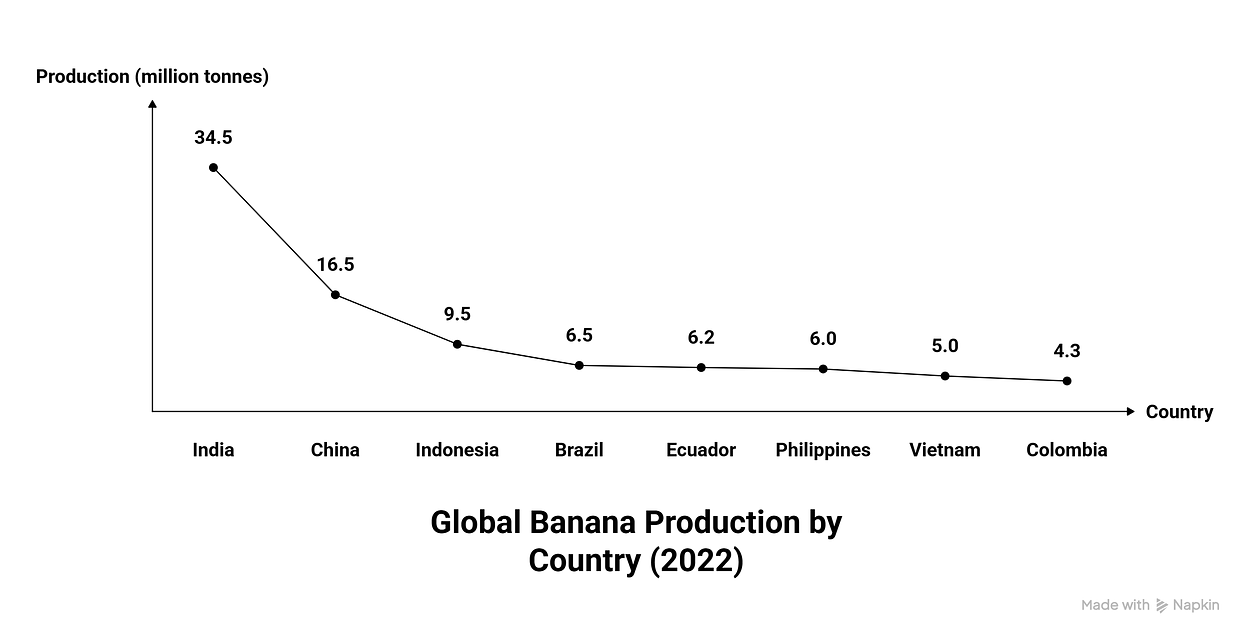

Bananas are one of the world’s most widely produced crops. FAO data indicate global banana production near 135 million tonnes (fresh fruit) in 2022 with production concentrated in Asia, Latin America and Africa; smallholders supply a large share of output. [1], [2] The banana plant is mostly water, and the harvest leaves large amounts of residual biomass: leaves, rachis, and — critically — the pseudostem (the trunk-like bundle of leaf sheaths). The pseudostem often comprises 60–80% of the above-ground plant mass and, depending on the production system, yields tens to hundreds of tonnes (fresh) per hectare per year of residual biomass that currently has limited commercial use. [3] This makes banana pseudostem one of the highest-volume agro-waste streams in tropical agriculture and a priority target for circular bio-economy interventions.

Quantifying the problem — production, pseudostem tonnage, and assumptions

Authoritative FAO reporting places global banana fruit production at ~135 million tonnes in 2022. Converting fruit tonnage to pseudostem biomass requires assumptions supported by the literature: several field studies and reviews report ~2.5–4.0 t pseudostem (fresh) per tonne of harvested banana fruit (range reflects cultivar and management) or roughly 60–220 t pseudostem fresh per hectare depending on planting density and cultivar. [3]–[6]

Using conservative midrange assumptions:

- Global fruit: 135 million t/year [1].

- Pseudostem generation: 2.5–4.0 t pseudostem per tonne fruit → ≈337.5–540 million t pseudostem fresh/year (global). [4], [5]

- Dry matter fraction: pseudostems are water-rich; dry matter typically 5–15% (sample data vary by region) → dry pseudostem ≈ 16.9–81.0 million t dry/year. [7]

- Carbon content (dry biomass) ≈ 40–50% C → stored C ≈ 6.8–40.5 million tC/year, equivalent to ~25–148 million tCO₂e (multiply tC × 3.667). (Calculation steps above use midpoint ranges; see assumptions footnote). [8]

These simple, transparent calculations show the order of magnitude: hundreds of millions of tonnes of fresh pseudostem waste annually, and tens of millions of tonnes dry biomass with a large latent carbon content. Regional examples (India, Ecuador, Brazil) will vary but follow the same scale logic. [2], [5]

Seasonality & supply variability. Banana is often harvested year-round in many tropical systems, producing a relatively steady stream of pseudostems. However, cultivar, local cropping systems, harvesting cycles and market shocks create spatial and temporal variability that affects collection logistics and processing economics. [3], [6]

Current disposal practices — what growers actually do

Common practices for pseudostem disposal include:

- Leaving to decay in field (natural decomposition): cheapest and common; returns organic matter to soil but may create localized nutrient overloads, pest habitat, and anaerobic patches that produce methane if waterlogged. [7]

- Open burning (pile/field burning): quick and inexpensive for clearing; emits CO₂ (biogenic), black carbon (BC) and co-pollutants (PM₂.₅), and has strong local air-quality and health impacts. [9], [10]

- Informal dumping or burning near settlements: prevalent where collection systems lack organisation; increases exposure risks and reduces reuse potential.

- Small-scale uses: feedstock for mulching, compost for farms, artisan uses and low-value construction material in some regions. These uses are patchy and often limited by labour and market access. [11]

Drivers: low cash margins, scarce labour, lack of transport/processing infrastructure, and limited technical awareness. Cultural norms (field hygiene, pest control) also drive burning or immediate removal rather than investing in collection and valorization infrastructure. [3], [11]

Climate & environmental impacts of disposal choices

Open burning

Open burning of pseudostems emits immediate CO₂ (biogenic) and black carbon (BC)/particulate matter that harms local air quality and accelerates radiative forcing at regional scales. Emission factors for field crop burning (EFs) from atmospheric inventories (Andreae & Merlet; Akagi et al.; IPCC EFDB) provide substance-specific EFs for PM, BC and trace gases; BC and organic aerosol emissions per kg dry biomass can be significant and spatially concentrated during burning seasons. [10], [12]

Anaerobic decay (unmanaged)

If pseudostems decompose anaerobically (e.g., in waterlogged piles or landfills), methane (CH₄) is produced; CH₄ has a high short-term climate forcing (GWP₁₀₀ ≈ 27–29 per IPCC AR6 guidance). Thus, unmanaged decay can produce substantial CO₂-equivalent impacts compared with controlled aerobic composting or energy recovery. [8], [13]

Illustrative emission arithmetic

Using a worked example (midpoint assumptions): 135 Mt fruit → 337.5 Mt fresh pseudostem (2.5 t/t fruit). Assume 10% dry matter → 33.75 Mt dry biomass. If dry biomass has 45% carbon → 15.19 Mt C → ~55.7 MtCO₂ of carbon released if biomass were combusted or fully oxidised. Note: national inventories may treat biogenic CO₂ differently; the climate relevance here is the timing of emissions, methane formed under anaerobic decomposition (high GWP), and the co-emitted BC and aerosols from open burning which have immediate health and radiative effects. [8], [12]

Air quality and health: crop residue burning is linked to spikes in PM₂.₅, respiratory illness and reduced local air quality; black carbon also affects regional climate and deposition on glaciers. [10], [13]

Waste-to-value alternatives — pathways, benefits and constraints

Key valorization routes for pseudostems include:

1. Fiber extraction for textiles & ropes (banana fiber)

- Benefits: replaces fossil-derived fibers, creates rural jobs, reduces waste, and produces biodegradable feedstock for textiles, paper and composites. Midstream processing can be labour-intensive (local employment). [11], [5]

- Constraints: requires mechanical/chemical extraction technology, drying and supply aggregation; fiber quality varies by cultivar and processing; market development needed. [5]

2. Anaerobic digestion (biogas)

- Benefits: produces renewable methane for local energy needs, yields digestate suitable as fertilizer, provides climate mitigation by displacing fossil fuels and avoiding methane from unmanaged decay. Studies report substantial CH₄ yields for banana stems (lab BMP tests show ~0.25–0.45 m³ CH₄/kg VS in optimized lab conditions), indicating strong potential for village-scale energy systems. [7], [14]

- Constraints: pre-treatment, logistics, co-digestion needs, capital for digesters, and operational know-how.

3. Composting / aerobic processing

- Benefits: returns nutrients to soil, reduces methane risk, low technology barrier; community composting can integrate residues with other organics.

- Constraints: land/time required, possible pathogen issues, transport costs.

4. Biochar production

- Benefits: produces stable carbon sequestered in soils, reduces net GHG compared to burning and may improve soil properties; biochar systems can generate heat or syngas as co-products. Some studies show biochar pathways can net reduce GHG substantially vs open burning. [15]

- Constraints: requires pyrolysis technology and market for biochar or incentives for soil carbon.

5. Briquettes/energy densification

- Benefits: replace fossil fuel for cooking/heating; mobilizes waste into a commodity.

- Constraints: drying energy, market acceptance and transport.

Each pathway carries trade-offs; success depends on local supply aggregation, investment, market access, and supportive policy.

Case studies — pilot examples

- Uganda — Texfad (artisan value chain): an enterprise purchased pseudostems, extracted fibers and created handicrafts for domestic and export markets, creating rural jobs and returning residues as soil amendments. Journalistic and NGO reporting documents employment growth and improved farmer incomes. [11]

- Ecuador scientific pilots (LCA studies): research teams evaluated banana rachis and pseudostem in composite materials and found environmental benefits when fibers substitute virgin polymer fillers and when local circular logistics are in place. [5]

These early examples indicate that with modest investment in processing and market development, pseudostem valorization can generate jobs and tangible emissions reductions.

Socio-economic & policy implications

Proper pseudostem management aligns with circular bio-economy goals and SDGs: it can create rural livelihoods (value chain jobs), reduce reliance on imported inputs, and sequester carbon or generate low-carbon energy. Policy levers include:

- Incentives/subsidies for collection infrastructure and small processor capital;

- Green procurement by public institutions to create demand for banana-fiber goods;

- Carbon finance: methodologies to claim avoided emissions from diverting biomass from burning/anaerobic decay to energy or biochar pathways;

- Technical training & cooperatives to aggregate supply and ensure consistent fiber quality and digester operation. [1], [5], [15]

Research gaps & recommendations

Key gaps:

- Improved, region-specific emission factors for pseudostem burning vs decay (Tier-2 inventory data). [12]

- Cost-scalability analyses for decentralized fiber extraction and AD (including transport). [5]

- Standards for banana fiber quality and end-use performance (textiles/ropes). [11]

Recommendations (policy & practice)

- Support pilot investments in village-scale AD and fiber extraction with matched technical assistance.

- Fund regionally representative GHG emission measurements for pseudostem burning and decay to inform inventories and carbon finance.

- Develop procurement windows (public buyers, tourism sector) for banana-fiber products.

- Create aggregation cooperatives to pool pseudostem feedstock and negotiate off-takers.

- Pilot biochar trials on degraded soils to quantify agronomic and carbon benefits.

- Foster standards bodies engagement to establish banana fiber quality metrics for industry uptake.

Call to action

Banana pseudostem is not just agricultural waste — it is a high-volume, under-priced resource with strong potential to reduce rural poverty and greenhouse-gas emissions if mobilized into circular bio-economy value chains. Researchers, funders, and policymakers should prioritise pilot validation (GHG and economic), supportive procurement, and locally-appropriate technology transfer so that pseudostems become feedstock rather than liability.

0 comments